leco hardness testing|leco testing equipment : importers Learn more with our latest Hardness Testing application notes. Hardness Determination in . There are only a few ways autoclave testing can FAIL and below you will find the types of failure; their causes, and what you can do. Biological tests are usually considered the most important test as they best reflect .

{plog:ftitle_list}

Use extreme caution to prevent electric shock. When a code ends in “0”, it means the unit had a power interruption during operating conditions. The operator may have unplugged the unit .

LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual and automatic model configurations for Microindentation, Macro-Vickers, Multi-Vickers, Brinell or Rockwell type testing.

Learn more with our latest Hardness Testing application notes. Hardness Determination in .Supporting accurate and efficient microindentation and Macro/Vickers hardness testing in fully .LECO offers a wide selection of hardness testing systems to match any application or budget. .

LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual and automatic model configurations for Microindentation, Macro-Vickers, Multi-Vickers, Brinell or Rockwell type testing.

Learn more with our latest Hardness Testing application notes. Hardness Determination in Decarburized Steel with AMH43. Hardness Profile in Decarburized Steel using AMH55Supporting accurate and efficient microindentation and Macro/Vickers hardness testing in fully automatic, semi-automatic, and lite configurations, the AMH55 is a valuable resource for users needing precise and productive hardness testing while tailoring the .LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual or automatic model configurations for Microindentation, Macro Vickers, Multi Vickers or Rockwell-type testing.

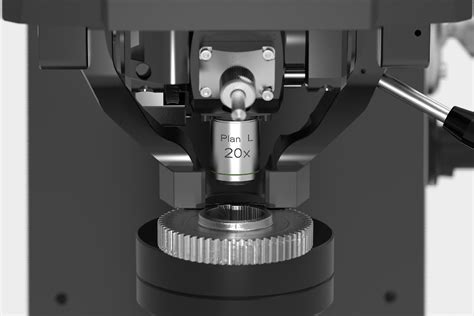

Supporting accurate and efficient microindentation and Macro/Vickers hardness testing in fully automatic, semi-automatic, and lite configurations, the AMH55 is a valuable resource for users needing precise and productive hardness testing while tailoring the . LECO's Cornerstone-based AMH55 system takes the human variance out of the process, making it fast, precise, and accurate, but just how much variance is actually involved? LECO decided to put it to the test, pitting seven humans of varying metallographic experience against the AMH55.

The AMH55 introduces LECO’s innovative CORNERSTONE ® brand software to our hardness testing platforms, for increased usability, simplified reporting, and streamlined analysis times. The AMH55 is ideal for: Case Depth Analysis | Coating Hardness | Surface Analysis | Powdered Metals | Weld Profiles | Fasteners | Decarburisation The AMH55 .

LECO Hardness Testing Systems MICROINDENTATION PRODUCT HIGHLIGHTS Video Capabilities (All Models) LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual or automatic model configurations for Microindentation, Macro Vickers, Multi Vickers or Rockwell-type testing.The AMH55 introduces LECO’s innovative CORNERSTONE ® brand software to our hardness testing platforms, for increased usability, simplified reporting, and streamlined analysis times. The AMH55 is ideal for: Case Depth Analysis | Coating Hardness | Surface Analysis | Powdered Metals | Weld Profiles | Fasteners | Decarburisation The AMH55 .Starting with a good standard test block is critical to confidence in your results, and that is why LECO offers a wide variety of test blocks to match all your laboratory’s needs. We can accommodate nearly any request for hardness test blocks for type, indenter, hardness, and load.LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual and automatic model configurations for Microindentation, Macro-Vickers, Multi-Vickers, Brinell or Rockwell type testing.

Learn more with our latest Hardness Testing application notes. Hardness Determination in Decarburized Steel with AMH43. Hardness Profile in Decarburized Steel using AMH55

macro hardness tester

Supporting accurate and efficient microindentation and Macro/Vickers hardness testing in fully automatic, semi-automatic, and lite configurations, the AMH55 is a valuable resource for users needing precise and productive hardness testing while tailoring the .

LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual or automatic model configurations for Microindentation, Macro Vickers, Multi Vickers or Rockwell-type testing.Supporting accurate and efficient microindentation and Macro/Vickers hardness testing in fully automatic, semi-automatic, and lite configurations, the AMH55 is a valuable resource for users needing precise and productive hardness testing while tailoring the . LECO's Cornerstone-based AMH55 system takes the human variance out of the process, making it fast, precise, and accurate, but just how much variance is actually involved? LECO decided to put it to the test, pitting seven humans of varying metallographic experience against the AMH55.

The AMH55 introduces LECO’s innovative CORNERSTONE ® brand software to our hardness testing platforms, for increased usability, simplified reporting, and streamlined analysis times. The AMH55 is ideal for: Case Depth Analysis | Coating Hardness | Surface Analysis | Powdered Metals | Weld Profiles | Fasteners | Decarburisation The AMH55 .

LECO Hardness Testing Systems MICROINDENTATION PRODUCT HIGHLIGHTS Video Capabilities (All Models) LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual or automatic model configurations for Microindentation, Macro Vickers, Multi Vickers or Rockwell-type testing.The AMH55 introduces LECO’s innovative CORNERSTONE ® brand software to our hardness testing platforms, for increased usability, simplified reporting, and streamlined analysis times. The AMH55 is ideal for: Case Depth Analysis | Coating Hardness | Surface Analysis | Powdered Metals | Weld Profiles | Fasteners | Decarburisation The AMH55 .

leco testing equipment

SES 2000 Vac (LS3) AUTOCLAVE Part 3 PART 3 MAINTENANCE n Disconnect and remove the chart recorder. WARNING o Refit the autoclave cover as described in para. 4. This procedure is done with the autoclave .

leco hardness testing|leco testing equipment